CNC CURVIC MACHINE

DETAILS

15″ PANEL I TOUCH SCREEN

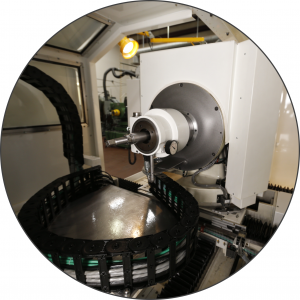

Diamond Roll Dresser Spindle

Workhead Spindle

HYDRAULIC SYSTEMS

Main Spindle Drive Motor and Heidenhain DA 400 Air Filter for Scale Purge System

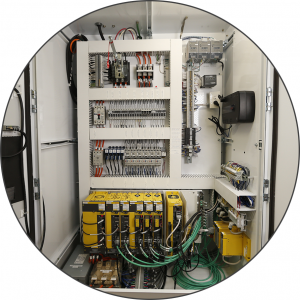

MAIN ELECTRICAL CABINET

Fanuc Servo Amplifiers

31IBS Computer with APC Battery Backup

HYDRAULIC CLAMPING CHUCK

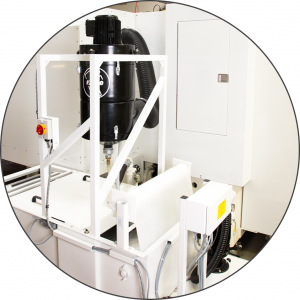

HOFFMAN FILTRATION SYSTEM

and integrated Royal Mist Collector with Swarf separator

SPECIFICATIONS

- Gleason Model 19 or 120 Cast Iron Base

- Computer controlled with the latest Fanuc Model 31IBS computer system

- Programming through Fanuc Panel I

- Solid State HDD with auto backup to USB Memory

- Fanuc 10 HP main spindle drive motor

- NSK precision ball screws and linear ways, 6 pts contact on X and Z Axis

- Heidenhain precision scales, 3nm accuracy grade

- Tandem opposing Fanuc servo motors driving B and C Axis transmitting the necessary torque through reduction gearboxes

- Latest Fanuc servo motors and controls

- Heidenhain Angle Encoders on B and C axis, 28 bit, C axis with 268 Million PPR

- All scales pressurized with clean air purge system to minimize contamination

- The machine is qualified by destructive metallurgical analysis of coupling teeth and meets stringent customer requirements for engine product

- Electrical cabinet consists of Allen Bradley solid state components

- Precision Roller Bearings supporting B and C Axis